Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

The Effect of Environmental Conditions on Drywall Installation & Finishing

Here at USG, we stand by our products. As an industry innovator with over a century of experience providing products and materials our customers have come to trust, we take claims about product performance very seriously.

While improper storage of products or expired materials will undoubtedly influence the quality of the final installed and finished system, it’s been found that a vast majority of our technical support is related to the environmental conditions and how they affect USG products. This is why it’s important to have a full understanding of outside factors that affect drywall installation and finishing.

Ideal Conditions

Construction has a penchant for weather delays, but it’s not without any good reason. If products are not installed under ideal conditions, it can lead to diminished performance and costly repairs.

The ideal conditions for installation, finishing, and decorating of gypsum materials are closely matched to intended occupancy environments. Anything too hot, too cold, too humid, etc. can impact product performance. This is why temperature, humidity, ventilation, and moisture should be maintained prior to stocking, installing, or completing finishing or final decoration.

Jobsite Conditions & Movement

There are three forms of outside influence or movement that can adversely affect final product performance:

- Thermal (temperature): can cause expansion & contraction of building materials

- ALL materials expand/contract differently and vary with the temperature

- Hygrometric (absorption of evaporated water): absorption and release of moisture change with environmental conditions

- Humidity can result in the expansion of materials and dry conditions can lead to the contraction of materials, both of which affect the physical strength of the material

- Structural (physical): movement of the building components; foundation settling or even wind and seismic forces apply

- Depending on the temperature rise/fall and humidity, buildings systems can either grow or shrink

Movement is the main reason why USG recommends control joints and perimeter relief to better account for any expansion or contraction experience on the jobsite.

Effects of Poor Conditions on Gypsum Board

Poor jobsite conditions can affect gypsum board. On their surface, it may seem like these effects are a result of poor-quality products, but the real issue tends to be more dependent on the environmental factors that result in movement on the jobsite.

- Ridging

- Panels are too tightly spaced, which causes them to bend outward and form a ridge in the joint

- Starved Joints

- Failure to adequately leave time for drying of joint compound after application can delay normal compound shrinkage, especially after it’s deemed “completed”

- Joint Edge Cracking

- Located at the edges of tape; caused by higher temperatures that accelerate drying or even cold/wet conditions that cause poor bond

- Joint Cracking

- Found at the center of flat or angle joints resulting from movement—either thermal, hygrometric, or structural

- Screw Depressions

- Low spots over fasteners caused by swelling of paper due to excessive humidity or free moisture that creates poor drying conditions

- Failure to use graduated arcs over fasteners will accentuate this phenomenon, as referenced in our recent Off the Wall podcast episode, “Unsung Heroes of Joint Compound—Levels of Finish”

- Nail Pops

- Shrinking in framing lumber

- Mold Potential

- Unmitigated exposure to water, high humidity, or poor ventilation can be conducive to mold growth

- Bond Loss

- Occurs when moisture is present in the panel at the time of finish/decoration

Appearance defects can also be affected by poor conditions. Variance in drying times can lead to paint color/texture variations, sheen, and even bubbling of the finish paint

Avoid the Pitfalls

Despite their drastic effect on construction materials, there are many easy ways to test and prevent negative jobsite conditions. In taking a few precautionary steps, you will save yourself time, effort, and most importantly, money.

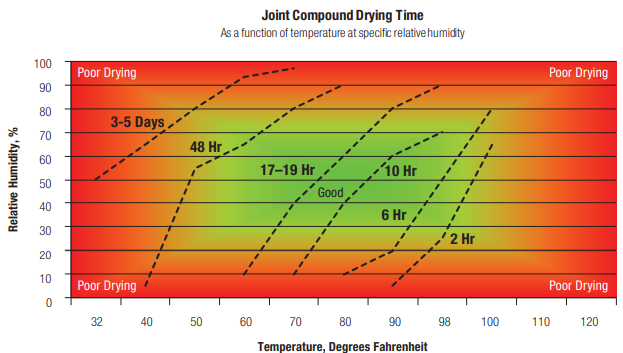

Using a Joint Compound Drying Time chart can be very helpful in this respect, giving you a simple reference guide by which to evaluate risk; just be sure to keep the temperature above 50 degrees Fahrenheit throughout the finishing process.

Measuring the surface temperature of the wall, as well as the temp/relative humidity of the air can also provide some insight. Surface temperature should always be maintained above the dew point throughout the curing process. In fact, referring to the dew point temperature can also help evaluate your job conditions. As a general rule, do not apply compounds or coating unless the surface temperature is at least 5 degrees above the dew point temperature of the room.

The use of HVAC systems before, during, and after installation and finish/decoration will also do wonders in keeping your jobsite under control. Keep the system on after work and on weekends to avoid large swings in environmental conditions. A free-standing heat source can be helpful in maintaining jobsite conditions, but never use un-vented, temporary heaters. They produce fumes that can stain surfaces as well as bleed through textures and paint. Additionally, propane and/or kerosene heaters add water vapor to the air as they burn, naturally raising the levels of humidity. If you do use a heater, it should never blow directly on the surface of the wall; this will cause rapid drying, cracking, and delamination.

The USG Solution

Environmental conditions can adversely affect the average jobsite but approach the situation with a unified and detailed plan to address round-the-clock environmental conditions. Not only will this ensure a smooth, seamless finish, but optimal environment conditions can eliminate call-backs and costly re-work, which are often more expensive to repair than the original work.