Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

Wind Uplift in Roofing: Long-Term Protection Leads to Less Call-Backs

There are two key factors of natural disaster preparedness that must be considered when building in areas susceptible to coastal storms: the resiliency of the building and the safety of its inhabitants. Depending on where construction is taking place, choosing building materials that will offer long-lasting protection over the lifetime of a building is extremely important.

With consideration to the exterior of a commercial building, combatting the effects of hurricane-category wind and rain involves added protection from moisture along with high wind-uplift ratings.

What is Wind Uplift?

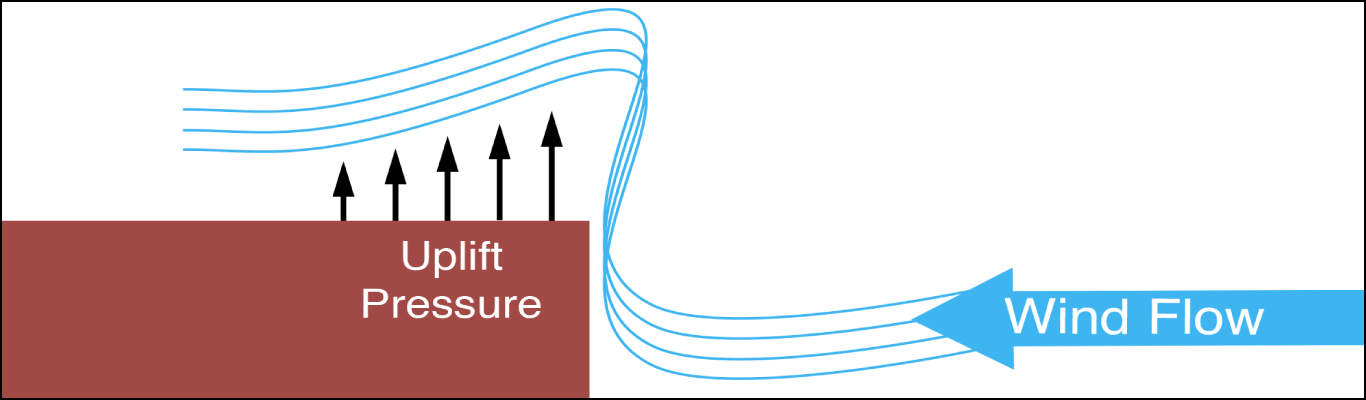

The pressure of wind flowing over and around a building can place a force on the roof, leading to damage or complete roof failure from both the impact of wind-borne debris and pressure created by the force of the wind.

Since a building obstructs wind flow, it causes airflow to change direction as it moves across the surface of the structure. According to the Certified Commercial Property Inspectors Association (CCPIA), wind uplift “occurs when the pressure below the roof is greater than the pressure above. This can be intensified during high winds, as air infiltrates into the building, causing an increase in air pressure below the roof, while the speed of the wind over the roof reduces the air pressure above it.”

Wind uplift creates a push-and-pull effect on the roof system that is measured in pounds per square foot (psf). If wind uplift creates a force much greater than what the roof was designed for, it will cause major problems throughout the entire system. Even if the roof stays intact after a bout of high winds, wind uplift can shift the roof components incrementally, weakening the roof over time.

On the Saffir-Simpson Hurricane Wind Scale, which categorizes hurricane intensity on a scale of 1 to 5, a Category 1 hurricane has wind speeds between 74-95 miles per hour. This level of wind activity is extremely intense, but a poorly maintained roof system can begin to fail at a strong gale, or 47-54 miles per hour.

The effects of the elements need to be considered at the design phase to future-proof your roof (and building). Building owners need to think about future costs of potential damage to a roof; how important are the building contents and what would be the cost to shut down building operations to make a repair are just a few of the questions they should be asking themselves.

Keep Your Roof Covered

The use of a roof cover board is integral to preventing damage to the roof and the building itself along with its interior. It’s equally important to select the right cover board for the job.

While cover boards are often overlooked when designing a roof system, they can offer many longstanding benefits to the entire building to prevent damage and potential call-backs after installation by preventing punctures and other impact damage while providing wind uplift value.

USG Securock® Brand Gypsum-Fiber Roof Board has exceptional wind uplift value as determined by FM Approvals, making it a perfect choice for areas that experience the effects of hurricane season. This roof cover board complies with the requirements of FM 4450 and FM 4470 and meets FM Class 1 designation, which must pass wind uplift resistance testing in addition to internal fire, external fire, foot traffic, corrosion resistance, impact resistance, and susceptibility to heat damage. And with high compressive strengths at 1,800 PSI, this roof cover board can handle impact, fire, and extremely high winds, and installs with fewer fasteners, creating jobsite efficiency for contractors.

Workers install USG Securock® Brand Gypsum-Fiber Roof Board on top of the Louis Armstrong New Orleans International Airport.

Roofing systems combined with STRUCTO-CRETE® Brand Structural Roof Deck Panels and other noncombustible materials create low- and steep-slope, 1- and 2-hour fire-rated roof-ceiling assemblies approved by Factory Mutual – FM Approval Standard 4472 and accepted by Miami-Dade County Department of Regulatory and Economic Resources (RER).

STRUCTO-CRETE® Roof Deck Panels are mechanically fastened to the steel joists of a roof structure.

STRUCTO-CRETE® Roof Deck Panels are strong, durable, fiber-reinforced cementitious panels affording great uplift ratings. The panels are dimensionally stable, will not buckle or warp like wood sheathing, and are factory-cured, therefore eliminating latent moisture issues like poured structural concrete. The panels are fastened to framing members to create a structural substrate for low- and steep-slope roof systems, canopies, and/or balconies. The roof system is designed to carry gravity and lateral loads. Roof membranes may be applied directly to the panels.

The USG Solution

This wind uplift machine at the Corporate Innovation Center simulates the effects of high winds on USG roofing products to ensure they perform up to expectations.

Each of USG’s products is tested and developed at our Corporate Innovation Center (CIC) testing facilities in order to bring only the best to market. Full-scale structural tests are performed using a 20' x 32' x 15' universal reaction frame which provides rigid support points for a variety of axial, trans-verse, shear and uniformed load tests. Wind uplift capacity tests are also conducted for both small-scale 5’x9’ and large-scale 12’x24’ roof assemblies, ensuring that our roofing systems can perform under extreme circumstances.

“All equipment at our Corporate Innovation Center is used as a development tool to accelerate the design and development process,” says Tim Kenny, Principal Researcher at the CIC. “This helps alleviate bottlenecks so we can get to market more quickly.” Testing our roof products against wind uplift values and delivering high-quality performance also allows USG to support contractors by ensuring they succeed with the highest-performing products and installation guides that comply with the code.

“Once a product is released, we’re still working on it for years to come,” says Kenny. “Constantly innovating and driving efficiencies to make things easier on contractors.”