Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

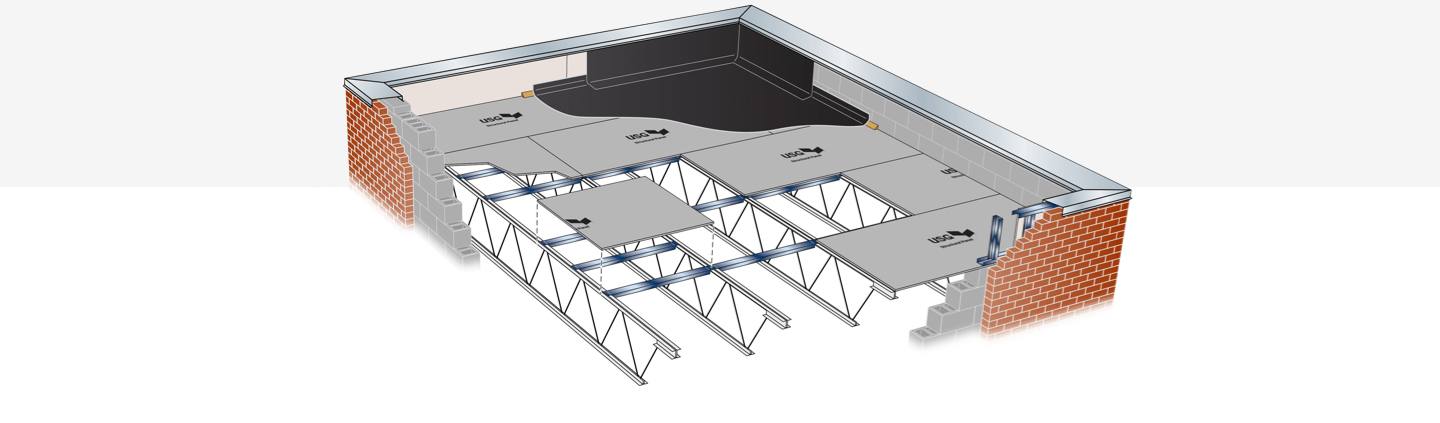

USG Structural Panel Concrete Roof Deck

USG Structural Panel Concrete Roof Deck

Outsmart The Lurking Menace Of Latent Moisture

Choose USG Structural Panel Concrete Roof Deck for a dry construction method that avoids moisture related risks inherent in poured concrete roof decks.

Performance

Low Slope Roof Deck

When Corporate Contractors, Inc. (CCI), took up the installation of USG Structural Panel Concrete Roof Deck they both simplified and sped up their work flow vs. traditional methods and products. See how CCI’s framing crew made use of USG support services during the installation of this mid-rise roof deck.

Product Benefits

Product Benefits

Dry Construction

A dry construction method that delivers strength and wind uplift performance normally sought in poured concrete decks.

Easy

A single layer roof deck solution with simple screw fastener panel assembly for both low- and steep-slope designs.

Fast

Roof assembly installation can occur immediately following the installation of our roof deck panels.

Light

A lighter weight solution than poured concrete that can reduce the use of steel in the overall structure.

FM Approved

The only noncombustible Structural panel sheathing in accordance with the FM standard 4472 for use in low- and steep-slope roof systems.

Dry Construction vs. Wet Construction

Dry Construction vs. Wet Construction

USG Structural Panel

Concrete Roof Deck

| Cure Time | Dry Time | Weight |

|---|---|---|

| 0Days to Cure | 0Days to Dry | 5PSF |

| Cure Time | 0Days to Cure | |

| Dry Time(Approx) | 0Days to Dry | |

| Weight(Approx) | 5PSF |

Normal Weight Concrete

| Cure Time | Dry Time | Weight |

|---|---|---|

| 28Days to Cure | 82Days to Dry1, 2 | 50PSF4 |

| Cure Time | 28Days to Cure | |

| Dry Time(Approx) | 82Days to Dry1, 2 | |

| Weight(Approx) | 50PSF4 |

Lightweight Aggregate Concrete

| Cure Time | Dry Time | Weight |

|---|---|---|

| 28Days to Cure | 160Days to Dry1, 3 | 30-40PSF4 |

| Cure Time | 28Days to Cure | |

| Dry Time(Approx) | 160Days to Dry1, 3 | |

| Weight(Approx) | 30-40PSF4 |

1. Research conducted by CTL Group as reported in the Portland Cement Association, Engineering Bulletin 119 (2008): page 42. Print.

2. 100 mm (4 in.) thick cast on two layers on 6-mil LDPE vapor retarder, moist cured for one week with burlap and plastic sheets, then air dry to 75% RH at 50 mm (2 in.).

3. 88 mm (3.5 in.) thick cast on top a 50 mm (2 in.) ribbed steel deck, moist cured for one week with burlap and plastic sheets, then air dry to 75% RH at 50 mm (2 in.).

4. Weight based upon 4" thick concrete slab.

Consult With Our Experts

Consult With Our Experts

Thanks! Someone will get back to you shortly