Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

Overview

Overview

The most widely used acoustical suspension system available, this economical, simple and versatile system allows for maximum access. Donn® Brand DX®/DXL™ Acoustical Suspension System is rust resistant and offers appropriate load-carrying capacities for acoustical panels, light fixtures and air distribution elements. The system can be used in both general and fire-rated applications.

Main Features

Donn® Brand DX®/DXL™ Acoustical Suspension System is made with a galvanized steel body that inhibits rust. Twist resistant, offering a clean look without exposed steel edges, it is available in a variety of colors to coordinate with USG ceiling panels.- 15/16" exposed tee system. Components for use in general and fire-rated applications

- Maximum economy and design simplicity

- Compatible with Logix™ Integrated Ceiling Systems

- DXL™ system features more than 80 UL designs (up to three hours)

- Cross-tee override-ends resist twisting and give a professionally finished look

- Meets or exceeds all national code requirements, including seismic

- Proprietary Quick-Release™ cross tees

- Available with High Recycled Content (HRC)

- ICC-ES evaluated for seismic installations (ESR-1222)

colors & finishes: Atmosphere 3681

Tees & Molding

Tees & Molding

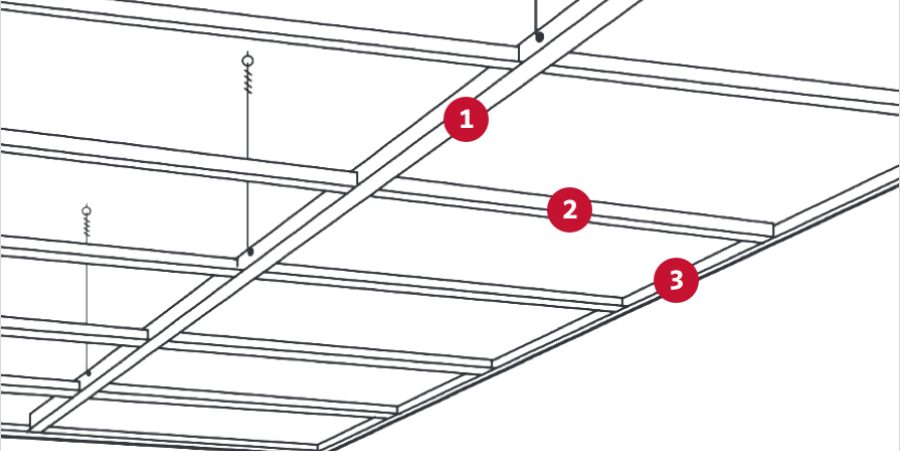

What do I need to build this Suspension System?

- KEY:

- 1) Main Tee

- 2) Cross Tee

- 3) Wall Molding

Estimate Your Ceiling Materials

Quickly and easily calculate how many ceiling panels, molding and tees you'll need for your project!

Main Tees

- Firecode®

| Item Number | ASTM Class | Length | Height | Fire Class | Seismic IBC | Rated Load | |||

|---|---|---|---|---|---|---|---|---|---|

| 4' Hanger Spacing | 5' Hanger Spacing | 6' Hanger Spacing | |||||||

| DX24 | Intermediate Duty | 12.00 foot | 1.64 inch | Class A | A-C | 12 lb./LF | 6.3 lb./LF | 3.7 lb./LF | |

| DXL26HRC | Heavy Duty | 12.00 foot | 1.64 inch | Firecode® | A-F | 16 lb./LF | 8.4 lb./LF | 5 lb./LF | |

| DXL26 | Heavy Duty | 12.00 foot | 1.64 inch | Firecode® | A-F | 16 lb./LF | 8.4 lb./LF | 5 lb./LF | |

| DXL24 | Intermediate Duty | 12.00 foot | 1.64 inch | Firecode® | A-C | 12 lb./LF | 6.3 lb./LF | 3.7 lb./LF | |

| DXL24-10 | Intermediate Duty | 10.00 foot | 1.64 inch | Firecode® | A-C | 12 lb./LF | 6.3 lb./LF | 3.7 lb./LF | |

Cross Tees

- Firecode®

| Item Number | Length | Height | Fire Class |

|---|---|---|---|

| DX416 | 4.00 foot | 1.00 inch | Class A |

| DX216 | 2.00 foot | 1.00 inch | Class A |

| DX3016 | 30.00 inch | 1.00 inch | Class A |

| DX2016 | 20.00 inch | 1.00 inch | Class A |

| DXL524 | 5.00 foot | 1.50 inch | Firecode® |

| DXL424 | 4.00 foot | 1.50 inch | Firecode® |

| DX422HRC | 4.00 foot | 1.50 inch | Class A |

| DX824 | 8.00 foot | 1.50 inch | Class A |

| DX624 | 6.00 foot | 1.50 inch | Class A |

| DX422 | 4.00 foot | 1.50 inch | Class A |

| DXL216 | 2.00 foot | 1.00 inch | Firecode® |

| DXL424HRC | 4.00 foot | 1.50 inch | Firecode® |

| DXL216HRC | 2.00 foot | 1.00 inch | Firecode® |

Documents & Files

Data Sheets & Specifications

| Data/Submittal Sheet (English) | PDF 1.3 MB |

| Architectural Specification (English) | DOCX 106.9 KB |

White Papers

| Sell Sheet (English) | PDF 2.5 MB |

Catalogs & Brochures

| System Catalog (English) |

| Brochure (English) |

Design Files

| CAD and Revit Files (English) |

Installation & Technical Manuals

| Technical Guide (English) |

| Installation Guide (English) |

SDS, Certifications & Reports

| VOC Emissions Certificate (English) | PDF 450.3 KB |

| SDS (English) | PDF 205.4 KB |

| SDS (Spanish) | PDF 61.8 KB |

| Evaluation Reports (English) | |

| Certificates (English) | PDF 1.1 MB |

Warranties

| Warranties (English) | PDF 147.7 KB |

Sustainability

| VOC Emissions Certificate (English) | PDF 450.3 KB |

| HPD (English) | |

| EPD (English) | PDF 571.3 KB |

| Declare Label (English) | PDF 827.5 KB |

Ask a question

Our customer support team will get back to you as soon as possible.

Question Guidlines

- Questions should relate to this product specifically.

- For help with pricing, availability, or delivery, please call 800.874.4968 (Monday–Friday, 7am–6pm Central)

- All questions and answers follow USG’s Terms & Conditions.

- Your question and USG’s answer may be posted to this page in the future, but none of your personal info will be included.

q & a

-

How is the load test data collected for ceiling grid?

Load data and spans are based on simple span tests in accordance with ASTM C635, with a deflection limitation of L/360.

-

What are the best grids to use in an area that is accessible to moisture?

The best grids to use in an area accessible to moisture are the Donn® AX™ Acoustical Suspension System or the Donn® ZXLA™ Acoustical Suspension System.

-

How do you remove cross tees without a tool?

To remove a cross tee, push up on the main tee with your thumbs (where the cross tee is connected) and rotate it until the cross tee pops up and out of the slot.

-

What gauge hanger wire is needed to install grid?

For residential installation 18-gauge wire is required. For commercial installation 12-gauge wire is required.

-

What is the warranty for a system, that uses USG tile and grid together?

There is a lifetime warranty on any ceiling system that is used in conjunction with our tile and grid. All grid is lifetime when used with USG tile, however not all tile is lifetime when used with USG grid. See complete warranty for details.

-

What is the standard warranty of grid?

Ten years. See complete warranty for details.

-

How is the spacing of wire hangers determined for fire-rated assemblies?

All systems must be installed and tested in compliance with ASTM C636.

-

When installing grid, what is the minimum clearance needed from the overhead structure?

Minimum clearance is 4", which allows ceiling tiles to be inserted and removed freely.

-

Which grid is the best grid to use in a Clean Room environment?

USG Donn® Brand CE™ Acoustical Suspension System is the best grid for a Clean Room environment.

-

How do you take main tees apart without a tool?

Facing the main tee splice place your left hand near the left side of the splice and right hand near the right side of the splice. Using a shearing motion, push with your left hand and pull with your right hand. This disconnects the main tee splice. Be sure to straighten the end tabs before attempting to reconnect.

-

Have a question?

Ask USGLet us do the research. We'll get back to you as quickly as we can.

-

Need help right away?

Call our Technical Support team at 800-874-4968 (Monday-Friday, 7:30 am - 4 pm Central).