Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

Hydro-Stone® Gypsum Cement

Exceptionally strong gypsum cement designed for stretch-press dies and producing cope-and-drag equipment.

Key Documents & Design Files

Overview

Overview

*High water absorption resistance.

Main Features

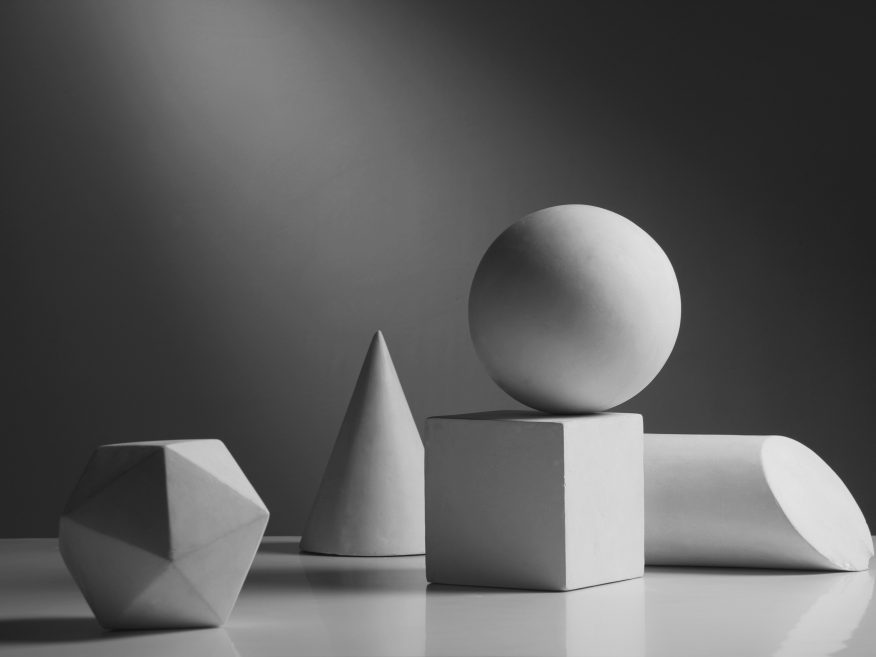

Hydro-Stone® Gypsum Cement is especially suitable where high strength and resistance to water absorption are necessary. It is ideal for applications in both the tooling & prototyping and art & statuary categories.Hydro-Stone® Gypsum Cement — For Tooling & Prototyping

Hydro-Stone® Gypsum Cement is ideal for stretch-press dies where extreme surface hardness is required. Offering greater expansion than Hydrocal® A-11 or B-11 gypsum cements, Hydro-Stone® Gypsum Cement:

- Features a heavy, syrupy consistency, ideal for pouring into solid models or patterns (and making it ideal for filling multiple molds simultaneously)

- Adapts to most flexible moulding compounds, due to its high absorption resistance

- Sets in 17-20 minutes, after machine mixing

- Requires 32 parts water by weight per 100 parts plaster.

Hydro-Stone® Gypsum Cement — For Art & Statuary

One of the hardest and strongest Hydrocal® products, Hydro-Stone® Gypsum Cement is used in the fabrication of high-quality art novelty and statuary castings. Offering excellent paintability, Hydro-Stone® Gypsum Cement:

- Can duplicate extremely fine details

- Works well in plaster and most flexible moulding compounds

- Is self-leveling, with low viscosity

- Provides fast set time for quick mold turns

Documents & Files

Data Sheets & Specifications

| Data/Submittal Sheet (English) |

Catalogs & Brochures

| Brochure (English) |

Installation & Technical Manuals

| Installation Guide (English) |

SDS, Certifications & Reports

| SDS (English) | |

| SDS (Spanish) | |

| Certificates (English) | PDF 158.1 KB |

Ask a question

Our customer support team will get back to you as soon as possible.

Question Guidlines

- Questions should relate to this product specifically.

- For help with pricing, availability, or delivery, please call 800.874.4968 (Monday–Friday, 7am–6pm Central)

- All questions and answers follow USG’s Terms & Conditions.

- Your question and USG’s answer may be posted to this page in the future, but none of your personal info will be included.

q & a

-

Can I color/tint plaster casts?

Yes. For uniform coloring, colorants can be added to the mix water and should be blended thoroughly. For varied color effects, colorants can be added to the slurry.

Both mineral colorants and water dispersed colorants are compatible with our plaster products.

-

Have a question?

Ask USGLet us do the research. We'll get back to you as quickly as we can.

-

Need help right away?

Call our Technical Support team at 800-874-4968 (Monday-Friday, 7:30 am - 4 pm Central).