Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

Evolution in Construction: USG Drywall and Suspension Systems

This article was adapted for the USG Blog, originally appearing on Walls & Ceilings.

From the beginning, USG established itself as an innovator in the construction manufacturing space. Even after 120+ years, innovation is still driving us to find “what’s next,” incorporating emerging technologies into our product categories that can help our customers work and build more safely and efficiently, making them more successful in the process.

But even with a future-forward vision, it’s important to reflect on the past innovations that shaped the construction industry as we know it today. Throughout USG’s storied history, we are proud to be innovators and first to market with two building product categories that have since become standards on jobsites across the nation: drywall and suspension systems.

Plaster » Wallboard » Sheetrock® Brand

Prior to the invention of what we now know as drywall, plaster derived from the mineral gypsum was the only material used to create walls in most building construction. Aside from plaster and lath, the industry had no other options for creating fire-resistant wall systems until inventor Augustine Sackett created the “Sackett Board” in 1894.

Consisting of a core panel of gypsum plaster sandwiched between two thick sheets of paper, Sackett Board was rigid but soft enough to admit nails, and tough enough not to crack during installation or ordinary use. Sackett Board could be installed on walls and ceilings in a single day, shaving weeks off the time needed to finish a building.

Augustine Sackett eventually partnered with United States Gypsum Company (now USG) to help market his revolutionary product, and USG continued to innovate on Sackett’s original design: in 1910, a “folded edge” was designed to keep the board from crumbling during installation; in 1913, interior plies of paper were eliminated, leaving a solid gypsum core; and in 1916, square edges were devised to join two panels flush along a wall.

Not only did this create a smooth surface that could be decorated without applying plaster, but it also helped coin the popular term “wallboard" that we know today.

By 1917, Sackett Board was rebranded to more adequately represent the quality and performance of the product. When USG helped introduce Sackett Board to construction, it created what we now know as the drywall industry, but the introduction of Sheetrock® Brand signified the beginning of a legacy built on quality, particularly its fireproof qualities and quick application.

The rest is history, as they say, but USG continues to innovate in our signature product category. In recent years, the Sheetrock® Brand Gypsum Panels portfolio has brought a range of firsts to the market, particularly in lightweight construction to improve workability and drive productivity on the jobsite, as well as advancements in sustainability, fire safety, and more.

- 2007 - Lightweight and sustainable 5/8 in. Type X gypsum panels with moisture and mold resistance

- Sheetrock® Brand EcoSmart Panels Mold Tough® Firecode® X

- 2010 - Lightweight 1/2 in. gypsum panels

- Sheetrock® Brand UltraLight Panels

- 2012 - Lightweight 1/2 in. moisture- and mold-resistant gypsum panels

- Sheetrock® Brand UltraLight Panels Mold Tough®

- 2018 - Lightweight and sustainable 5/8 in. Type X gypsum panels

- Sheetrock® Brand EcoSmart Panels Firecode® X

- Sheetrock® Brand EcoSmart Panels Firecode® X

Suspend Your Disbelief

While cold-formed steel was introduced into construction in the early 1900s, the first iteration of suspended lath and plaster systems were also being installed using rigid metal rods coated black for corrosion resistance to support steel channels and metal lath. Though innovative, these systems were heavy, labor-intensive, and inflexible, relying on 8- and 12-gauge wire to splice cold-rolled and hat channels together.

USG has long been a driving force in suspended ceiling innovation, combining decades of engineering expertise with a commitment to simplifying construction. A pivotal moment came in 1986 with the acquisition of Donn Corporation, founded by Don Brown, pioneer of the modern drop ceiling. This positioned USG as a leader in integrated ceiling solutions, blending Donn® Brand grid with its acoustical tile portfolio.

From early breakthrough innovations like The Donn Click™ and Quick-Release Clip to the launch of USG Drywall Suspension System in 1998, USG has consistently raised the bar for performance and ease of installation. The USG Westlake, OH plant, once Donn’s headquarters, remains USG’s flagship grid operation, producing over 60 profiles and supporting custom fabrication across North America.

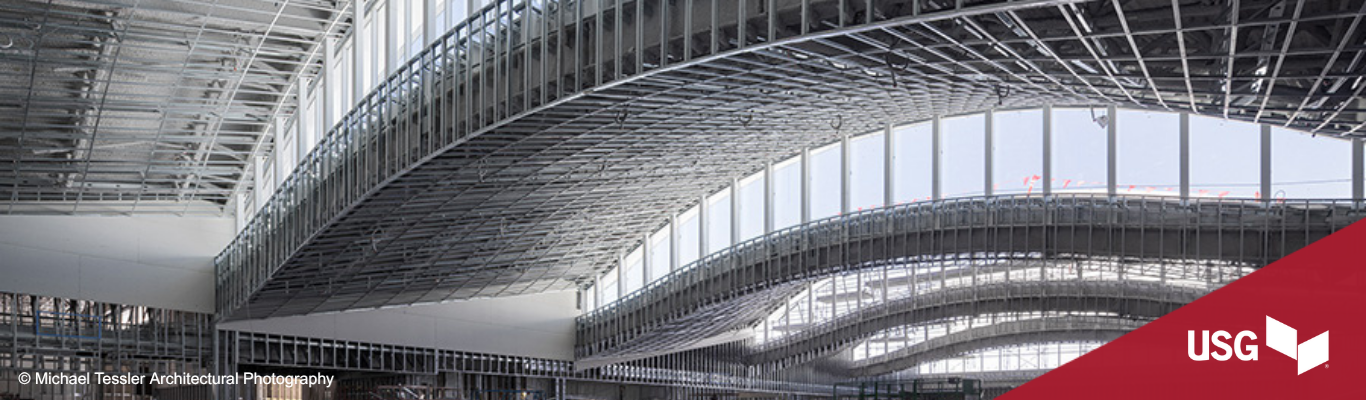

As an industry first, USG Drywall Suspension System streamlined ceiling construction with lightweight grids that reduce labor and material costs, making monolithic drywall ceiling installations a breeze. Featured products within the portfolio include the Wall-to-Wall System, ideal for corridors and tight plenums, eliminating hanger wires in spans up to 9 feet, and the Curved System enables dramatic architectural designs like domes and waves without extra components.

Backed by ICC code approvals and over 60 fire-rated assemblies, USG’s suspended ceiling systems empower architects and contractors to build smarter and faster without compromising on performance or aesthetics.

The industry’s first:

- 1987 – Drywall furring strip system with interlocking carrying channel

- 1996 – Quick-release clip design, making grid demountable without tools

- 1998 – Engineered suspension system designed for wallboard ceilings

Sound Performance You Can Hear, Not See

To further the field of suspended drywall ceilings, USG turned to customer insights to drive innovation. Recognizing the demand for the smooth, monolithic look of acoustic plaster without the complexity of traditional installation, USG developed the Ensemble® Acoustical Drywall Ceiling system in 2018, the industry’s first solution to marry high-end aesthetics with the simplicity of drywall and ceiling grid systems. This breakthrough solution delivers superior acoustic performance while maintaining a seamless finish.

Building on this success, USG recently introduced Ensemble® RAP Acoustical Drywall Ceiling, addressing a critical challenge in return air plenum designs. Unlike competing systems that require extra components, Ensemble® RAP integrates a film backer to prevent air leakage, reduce soiling, and maintain acoustic integrity within a single, streamlined system.

The industry’s first:

- 2018 – Integrated ceiling system for acoustic drywall

- 2024 – Integrated ceiling system for acoustic drywall in return air plenum application

The USG Solution

USG draws on a storied history of “firsts” in combination with a commitment to collaboration to ensure our solutions meet real-world needs across various sectors. Whether your project is in the design phase or if you’re preparing for bid, USG understands that no two projects are the same.

With engineering services to work through installation details and jobsite support from USG Contractor Specialty Reps to ensure a flawless and efficient finish, USG is prepared to help you solve the challenges standing in the way of true project success.