Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

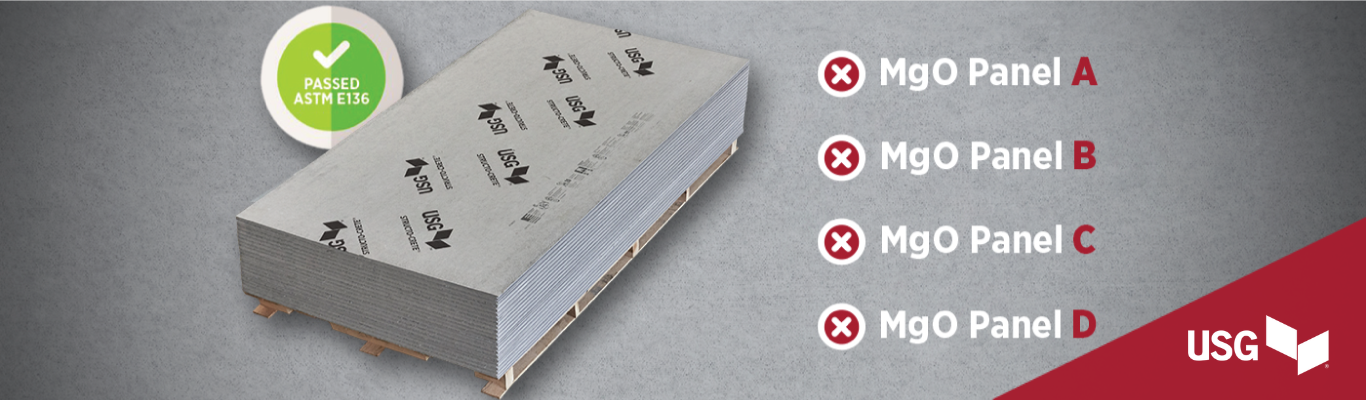

The Burning Truth of MgO: Fire Safety Demands Proven Performance

In the construction industry, fire safety is non-negotiable. Extensive code compliance isn’t just a box to check, but rather a critical safeguard for both life safety and professional liability. That’s why it’s essential to specify building materials that deliver on their performance claims, particularly in regard to their manufacturer’s claims of noncombustibility.

While poured concrete floors offer reliable fire performance, their immense weight and prolonged setting times can cause limitations and roadblocks during installation. As a result, Magnesium Oxide (MgO) structural panels have emerged as a cost-effective replacement for poured concrete floors, but recent independent testing has revealed that these panels may not be as advertised.

Testing Tells a Different Story

In 2020, USG commissioned third-party testing of three leading MgO structural panels in the US market to evaluate their compliance with the industry standard for noncombustibility: ASTM E136. The results could not have been clearer—none of the panels passed.

ASTM E136, Standard Test Method for Assessing Combustibility of Materials Using a Vertical Tube Furnace at 750°C, requires that materials withstand exposure to 750°C without exceeding specific temperature thresholds that maintain structural integrity during an active fire to allow for adequate reaction for evacuation of the structure. All tested MgO samples—Megaboard, DragonBoard, and NOCOM—failed, with temperatures exceeding the failure limit of 780°C (1436°F), confirming that these MgO structural panels do not meet the International Building Code (IBC) requirements for noncombustible materials in Types I and II construction.

Per ASTM E136 “Commentary” Section X1.5.1.1, any material with more than 3% combustible content has significantly increased odds of failing the noncombustibility test. The tested MgO panels contained Total Organic Carbon (TOC) levels ranging from 3.61% to 7.29%, meaning that these panels were likely to fail the test before it even started. In stark contrast, USG STRUCTO-CRETE® Structural Panels contain just 0.83% TOC, reinforcing claims of proven noncombustibility.

An Industry that Deserves Transparency, Accountability

Those associated with the manufacture and sale of MgO structural panels may point to code reports and outdated test reports that supposedly support their claims of noncombustibility. However, those reports either relate to panels of different thicknesses or fail to provide adequate detail supporting their conclusions.

Following the release of USG’s whitepaper on this topic, the International Code Council (ICC) withdrew Megaboard’s ICC-ESL-1151 report in 2021. USG also issued cease-and-desist letters to the manufacturers of all three panels, demanding an end to their misleading marketing tactics that have real-world consequences.

In response to the fallout of these findings, a fourth manufacturer that was not included in the test, Huber Engineered Woods, no longer advertises or promotes their MgO EXACOR/extremegreen panels as noncombustible or suitable for use in noncombustible applications.

The Safer, Smarter Alternative

When life safety and code compliance are on the line, USG STRUCTO-CRETE® Brand Structural Panels offer a tested and trusted solution, backed by rigorous third-party testing and decades of innovation, and manufactured in Delavan, WI.

Don’t compromise on fire safety; choose the panels with a proven track record that meet ASTM E136 standards and provide the performance you can count on with USG.

Additional information on study findings as well as details regarding the proven noncombustibility of USG STRUCTO-CRETE® Brand Structural Panels can be found here.