Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

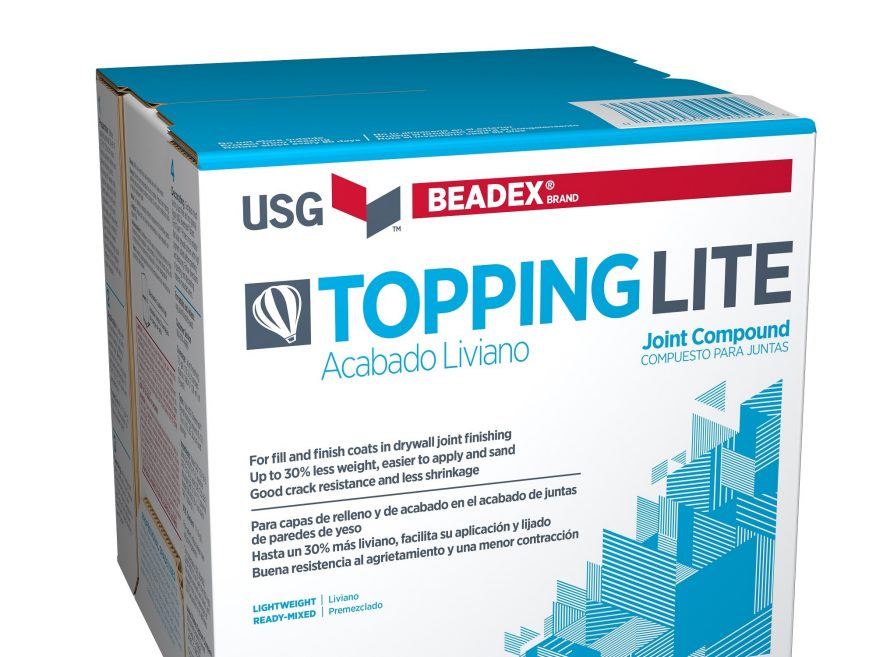

Beadex® Brand Topping Lite Joint Compound

Lightweight, smooth, joint finishing compound for use in second and third finishing coats.

Overview

Overview

Sands easier and faster than conventional-weight compounds and weighs up to 30-percent less. Beadex® Brand Topping Lite Joint Compound is a lightweight, smooth, joint finishing compound for use in second and third finishing coats.

Main Features

Beadex® Brand Topping Lite Joint Compound features a high-performance formulation used for filling, leveling, and applying finishing coats over gypsum panels. It is recommended for use with Beadex® Brand Taping Lite Joint Compound and USG Beadex® Brand All Purpose Lite Joint Compounds for application of second and third finishing coats.- Weighs up to 30-percent less than conventional-weight topping compound

- Features increased crack-resistance, lower shrinkage, and easier sanding properties

- Requires only minimal mixing, thinning, and retempering

- Accepts water quicker than conventional compounds, reducing solution times

- Delivers easy workability and excellent slip and bond

- Not recommended for embedding tape, skim coating, or texturing

- Meets ASTM C475.

Specifications

Sustainability

- GREENGUARD Certification Yes

Physical Data

- Coat Type Final

Installation

Installation Guide PDF 7.4 MB

Documents & Files

Data Sheets & Specifications

| Data/Submittal Sheet (English) | PDF 728.8 KB |

White Papers

| White Paper (English) | PDF 329.7 KB |

Installation & Technical Manuals

| Technical Guide (English) | PDF 428.6 KB |

| Installation Guide (English) | PDF 7.4 MB |

SDS, Certifications & Reports

| SDS (English) | PDF 854.2 KB |

| SDS (Spanish) | PDF 812.2 KB |

Sustainability

| HPD (English) | |

| EPD (English) | PDF 952.1 KB |

Ask a question

Our customer support team will get back to you as soon as possible.

Question Guidlines

- Questions should relate to this product specifically.

- For help with pricing, availability, or delivery, please call 800.874.4968 (Monday–Friday, 7am–6pm Central)

- All questions and answers follow USG’s Terms & Conditions.

- Your question and USG’s answer may be posted to this page in the future, but none of your personal info will be included.

q & a

-

Can fiberglass tape be set with drying-type compounds?

No. When using fiberglass tape, only setting-type joint compounds like Sheetrock® Brand Durabond® and Sheetrock® Brand Easy Sand™ should be used for the first coat over the tape. Ready-mixed drying-type compounds can be used for subsequent finishing coats.

-

What is the best way to store ready-mix compound for another use?

Clean sides and lid of container so no dried compound falls into the mixture. Level joint compound surface with a knife and cover container tightly. If storing, cover leveled surface of joint compound with approximately 1/2" of clean water and cover container tightly. Pour off water before reusing joint compound. Do not store in direct sunlight and protect from extreme heat and cold. The shelf life of an unopened container is up to nine months under proper storage conditions.

-

Can ready-mixed joint compound be used on exterior applications?

No. Sheetrock® Brand Setting-Type Joint Compounds (Durabond® and Easy Sand™) are recommended to treat joints in exterior gypsum ceiling board.

-

Why do stains appear when retexturing a wall or ceiling?

Over time stains settle into a wall or ceiling. When that area is retextured the stains photograph through causing a yellowing or browning effect. The best way to prevent staining is to apply a stain blocker, primer, and sealer.

-

How long does it take joint compound to dry?

Under conditions of a temperature of 70° and 70% humidity, joint compound should dry in about 24 hours. Higher humidity and/or lower temperatures will slow drying time.

-

Can I use two different joint compounds on the same joint? Can I mix two joint compounds together to save time?

Yes, different joint compounds can be used over each other.

No, different joint compounds should never be mixed with each other.

-

What is the fire rating of joint compound?

Joint compound does not have a fire rating by itself, but does meet ASTM C475. When fire testing a wall the fire rating is not for individual products, but for all the system components together. USG Joint Compounds are used in numerous fire-tested assemblies. These are outlined in USG Publication SA100 Construction Selector.

-

Can additives be mixed into joint compound?

There are various products in the market which, when mixed with joint compounds, claim to improve various performance attributes of joint compounds.

USG does not endorse the use of additives in USG joint compounds for the following reasons:

An additive can adversely affect the unique balance of the many performance attributes each joint compound has been formulated to provide.

It is virtually impossible for an additive manufacturer to know if their additive is compatible at all times with all of USG's product formulations.

USG has no control over the manufacture and quality of additives manufactured by others.

Note - For taping and finishing joints, water can be added as necessary. USG recommends adding water in increments of a half-pint to avoid over thinning.

See USG Technical Information Sheet J1716 for more information.

-

What is the biggest gap between joints that can be filled with joint compound?

The maximum gap should not exceed 1/8 of an inch.

-

Have a question?

Ask USGLet us do the research. We'll get back to you as quickly as we can.

-

Need help right away?

Call our Technical Support team at 800-874-4968 (Monday-Friday, 7:30 am - 4 pm Central).