Sign In

You're All Set

Welcome back! You are now signed in.

You have been logged out

You have been logged out due to inactivity

Forgot Password

Please enter the email address you used to create the account. We'll send you a link that lets you create a new password.

You're All Set

Please check your email. Click the link in the email to create a new password.

Reset Password

You're All Set

Success! Your password has been updated.

Change Password

You're All Set

Success! Your password has been updated.

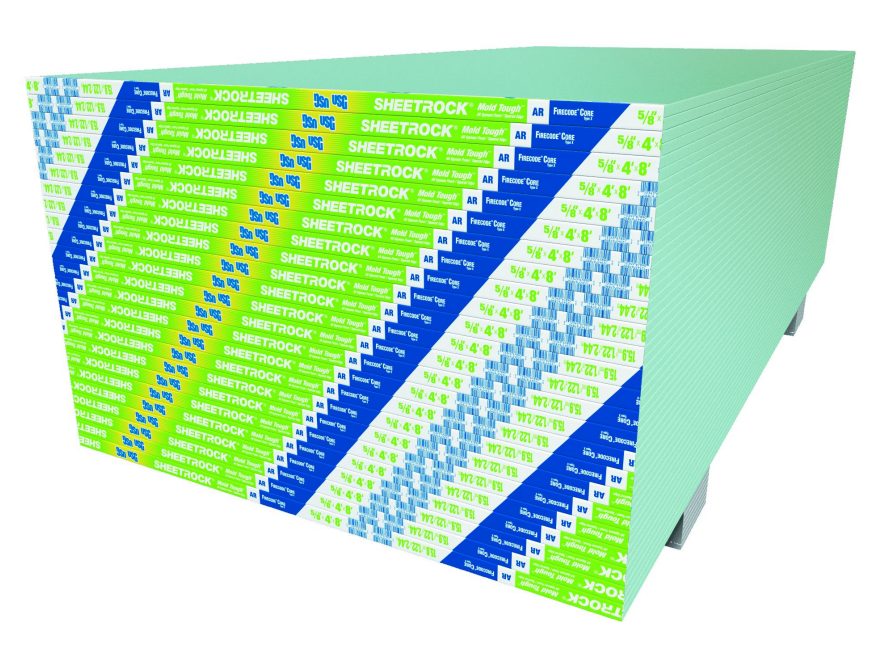

Sheetrock® Brand Mold Tough® AR Firecode® X Panels

5/8 in. (15.9 mm) Type X panels with abuse, moisture and mold resistance

Overview

Overview

Main Features

- 5/8 in. (15.9 mm) Type X wallboard with moisture, mold and abuse resistance

- Feature a noncombustible, moisture-resistant gypsum core encased in moisture- and mold-resistant, 100% recycled green face and brown back papers

- Designed and tested to offer greater resistance to surface abrasion, indentation and impact damage than 5/8 in. (15.9 mm) Sheetrock® Brand Mold Tough® Firecode® X Panels

- Comply with ASTM C1396, Standard Specification for Gypsum Board, for 5/8 in. (15.9 mm), Type X and water-resistant gypsum wallboard

- When tested in accordance with ASTM D3273, Standard Test Method for Resistance to Growth of Mold on the Surface of Interior Coatings in an Environmental Chamber, the panels meet or exceed ASTM C1396 specifications

- Tested to ASTM C1629, Standard Classification for Abuse-Resistant Nondecorated Interior Gypsum Panel Products and Fiber-Reinforced Cement Panels, for surface abrasion and indentation resistance, and soft- and hard-body impact

- Underwriters Laboratories Inc. (UL) Classification as to fire resistance, surface burning characteristics and noncombustibility

- Achieved GREENGUARD Gold Certification and qualifies as a low VOC emitting material (meets CA 01350)

Applications

- Administrative Offices

- Auditoriums and Gymnasiums

- Bars Restaurants and Dining Areas

- Cafeterias

- Classrooms

- Convention and Meeting Rooms

- Corridors and Hallways

- Department Stores and Boutiques

- Dormitories

- Executive Areas, Conference Areas and Board Rooms

- Galleries and Exhibit Spaces

- Grocery Stores

- Guest Rooms and Suites

- Health and Fitness

- Kitchens and Food Prep Areas

- Laboratories, Operating Rooms and Imaging Rooms

- Lobbies and Reception Areas

- Mall Interior Spaces

- Mechanical Rooms

- Media Centers, Music Rooms and Libraries

- Multi-Family Residential and Condos

- Nurseries and Birthing Rooms

- Open Plan Offices

- Patient Rooms

- Restrooms, Utility Rooms and Loading Docks

- Stairways and Elevator Shafts

- Theatres

- Traditional Offices

Specifications

Performance

- Mold & Mildew Resistance Yes

-

Fire Resistance

- Fire Rating Type X

-

ASTM E84

- Flame Spread 15

- Smoke Developed 5

- Fire Rating Type X

-

ASTM Type

ASTM C1396; ASTM C1629; ASTM C473; ASTM D3273; ASTM E136; ASTM E84

- Flame Spread 15

- Smoke Developed 5

- Fire Rating Type X

- UL Type Designations AR

Sustainability

- GREENGUARD Certification Yes

Physical Data

- Thickness (in.) 5/8

- Edge Square Edge; Tapered Edge

- Panel Size 48 in. x 8-14 ft.

- Nominal Weight 2.8 lb./sq. ft.

Documents & Files

Data Sheets & Specifications

| Data/Submittal Sheet (English) | PDF 280.0 KB |

| Architectural Specification (English) | DOCX 126.0 KB |

White Papers

| White Paper (English) | PDF 729.3 KB |

| Sell Sheet (English) | PDF 2.7 MB |

Catalogs & Brochures

| System Catalog (English) |

| Brochure (English) |

Design Files

| CAD and Revit Files (English) |

Installation & Technical Manuals

| Technical Guide (English) | PDF 128.2 KB |

| Installation Guide (English) |

SDS, Certifications & Reports

| SDS (English) | PDF 530.9 KB |

| SDS (Spanish) | PDF 569.3 KB |

Sustainability

| HPD (English) |

| Greenguard Certificate (English) |

| EPD (English) |

Ask a question

Our customer support team will get back to you as soon as possible.

Question Guidlines

- Questions should relate to this product specifically.

- For help with pricing, availability, or delivery, please call 800.874.4968 (Monday–Friday, 7am–6pm Central)

- All questions and answers follow USG’s Terms & Conditions.

- Your question and USG’s answer may be posted to this page in the future, but none of your personal info will be included.

q & a

-

What is the maximum spacing allowed between gypsum panels over framing?

The maximum space allowed between panels is 1/8 of an inch. Any space larger can lead to problems with joint finishing cracking.

-

Can gypsum panels be installed horizontally?

Gypsum panels can be installed horizontally or vertically. Installing the board horizontally lessens the total amounts of joints to be taped by 25%.

-

What is the recommended fastener spacing for attaching gypsum panels to walls and ceilings in non-fire-rated assemblies?

When nailing to wood construction the spacing is 7 inches for ceilings, and 8 inches for walls. When screwing into wood and steel framing the spacing is 12 inches on ceilings and 16 inches for walls. Refer to the relevant fire test to determine fastener type and spacing.

-

What is the maximum temperature that Sheetrock® Brand Gypsum Panels can withstand?

Sheetrock® Brand Gypsum Panels can withstand temperatures up to 125°F.

-

What is the recommended spacing of control joints for gypsum panels for walls and ceilings?

Control joints shall be installed where a wall or ceiling runs in an uninterrupted straight plane exceeding 30 linear feet. For ceilings with perimeter relief, the spacing is not to exceed 50 linear feet.

-

What is the recommended application for fastening gypsum panels to walls and ceilings?

When nailing to wood construction the spacing is 7 inches for ceilings, and 8 inches for walls. When screwing into wood and steel framing the spacing is 12 inches on ceilings and 16 inches for walls. Refer to the relevant fire test to determine fastener type and spacing.

-

When hanging gypsum panels on the ceiling should the board be applied parallel or perpendicular?

Half-inch panels must be applied perpendicular and 5/8 inches can be applied either way.

-

Have a question?

Ask USGLet us do the research. We'll get back to you as quickly as we can.

-

Need help right away?

Call our Technical Support team at 800-874-4968 (Monday-Friday, 7:30 am - 4 pm Central).